PROFILED LINE MARKINGS - KEEP THE ROADS SAFE WITH DURABLE, HIGH-PERFORMANCE ROAD MARKINGS!

Visible linear markings are crucial in order to make sure that drivers stay in the right lane and are able to find their way even in bad weather conditions.

HIGH VISIBILITY DURING RAINY WEATHER

The drainage effect of the profiled markings ensures that rainwater will easily drain away from the lines. As a result, the lines are able to maintain high reflective values in rainy weather. This is possible thanks to the structure that allows the water to drain.

HIGH LINE VISIBILITY AT NIGHT TIME

Due to their shape and vertical walls, as well as the possibility of pre-mixing glass beads, profiled lines have a higher retro-reflective level compared to flat lines. This increases the visibility in poorly illuminated areas and during night time.

NOISE ALERT TO AVOID RUN-OFF-ROAD COLLISIONS

Furthermore, the profiled nature of the road marking produces a noise when driven over that will warn the driver against driving off the road. Therefore, profiled markings are often used on roads with high traffic and low night visibility as highways and motorways.

Materials to make profiled markings:

Profiled markings can be made with either hot applied thermoplastic or cold-applied 2-component material. You need to be aware of the quality of the material you are using since this is the basis for a good and lasting line marking result. The long lifespan of both types of material, when applied correctly, makes them a cost-effective solution as they demand less frequent maintenance or replacement.

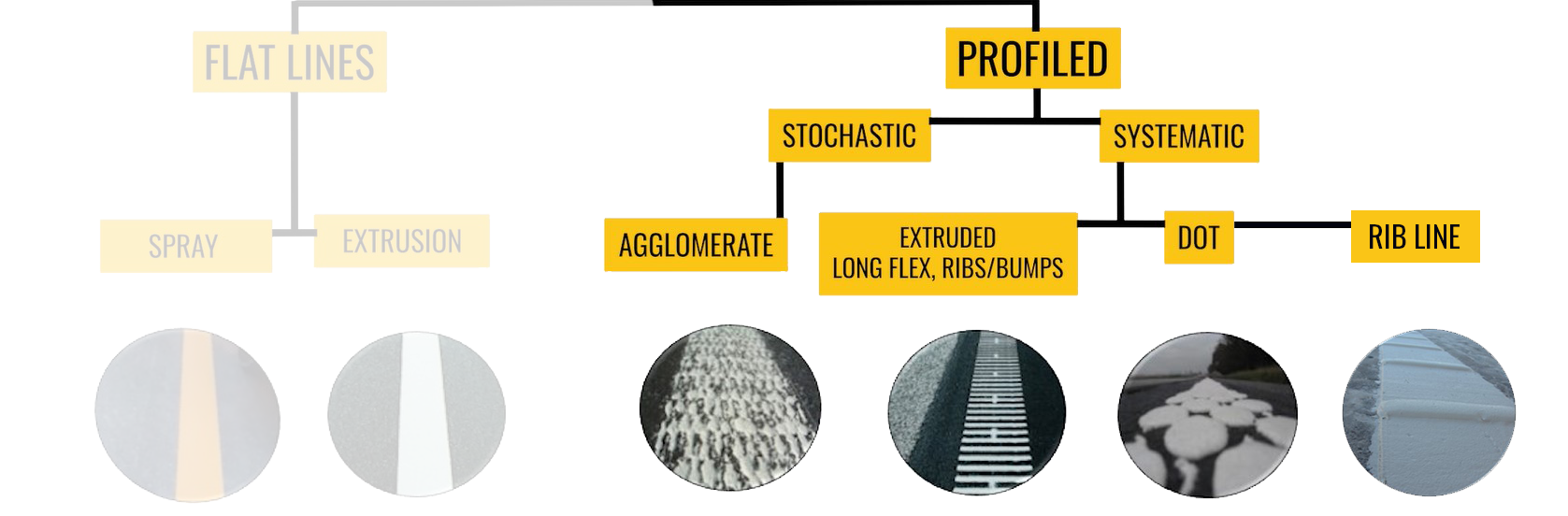

Various line types

THERMOPLASTIC

Hot-applied thermoplastic is a solid compound containing pigments, glass beads, binder and filler which becomes liquid when heated. To ensure the supply of hot melted thermoplastic for a continuous road marking process, a supply truck with thermoplastic preheaters are melting, heating and mixing the thermoplastic material making it ready for application via the road marking machine. See the links below for the different types of profiled markings that can be made with Borum thermoplastic machines.

2-COMPONENT MATERIAL

There are different kinds of 2-component systems, such as 50:50 or 98:2. At Borum we have chosen to work with the 98:2 system; 98% paint and 2% hardener. When the paint and the hardener are mixed, the curing process starts instantly and you should start the application on the road immediately. When the application is done or there is a break in the work, the 2-component system needs immediate flushing out. See the links below for the different types of profiled markings that can be made with Borum 2-component machines.