The thermoplastic extruder is used for applying both flat lines (also known as non-profiled or type 1 markings) and profiled markings (also known as structured or type 2 markings).

Extrusion of thermoplastic material is the classical solution to achieve a safe and cost-effective road marking, ensuring long durability even at demanding road types.

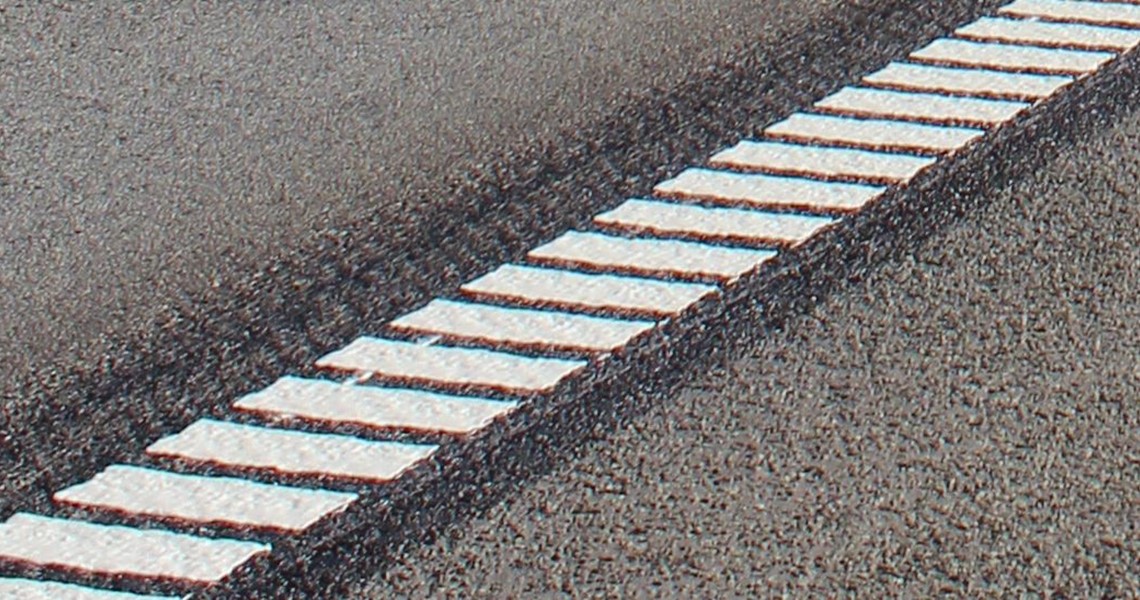

Profiled road markings are the safest road marking technology, where a part of the road marking typology is raised over the road surface. This type of markings are becoming more and more popular because of the increased road safety it provides due to high visibility in wet conditions and at night, as well as the acoustic warning you get when driving on the line.

With this extruder solution, Borum has for decades been setting the standard in the industry making it possible to fulfil the marking requirements set by road authorities worldwide.

The quality of the line, the uniform thickness and width, the beginning and end of each line, and the easy control of the equipment from the LineMaster computer are all key elements when it comes to what makes the Borum Thermoplastic Extruder differ from other products on the market.

Learn more about the different features of the extruder in the video below or read more further down the page.

Different line widths

The extruder may be used for the application of single, double and triple lines of different width, for simultaneous application of solid and broken lines, and various types of profiled lines as well.

Effective heat transfer oil for all significant parts of the extruder

This feature ensures, that the thermoplastic material has the right temperature and does not stiffen and set inside the equipment. Borum uses a centrifugal pump, which opposite to often-used gear pumps, increases the flow of oil when the heat transmission oil heats up.

AUTOMATIC CLEANING FUNCTION

The cleaning function is triggered by the push of a button from the machine's LineMaster computer and can be activated while driving. This will open all active shutters up high and push the extra material out.

Continuous circulation of the thermoplastic material inside the equipment

The main advantage of the Borum extruder is a special system of thermoplastic recirculation in the area of the shutters, which prevents the material disintegration and clogging up of the extruder outlet. Only “fresh” material is delivered to the open shutters. At the same time, there is constant circulation near the closed shutters. The circulation of the material and its delivery out of the tank is carried out with the help of the hydraulically driven screw pump.

Build-in pressure regulating system

It ensures that line width and thickness does not change no matter the number of shutters involved in the current marking assignment. Even when extruding a broken line next to a solid one, there will be no negative interaction between the individual lines.

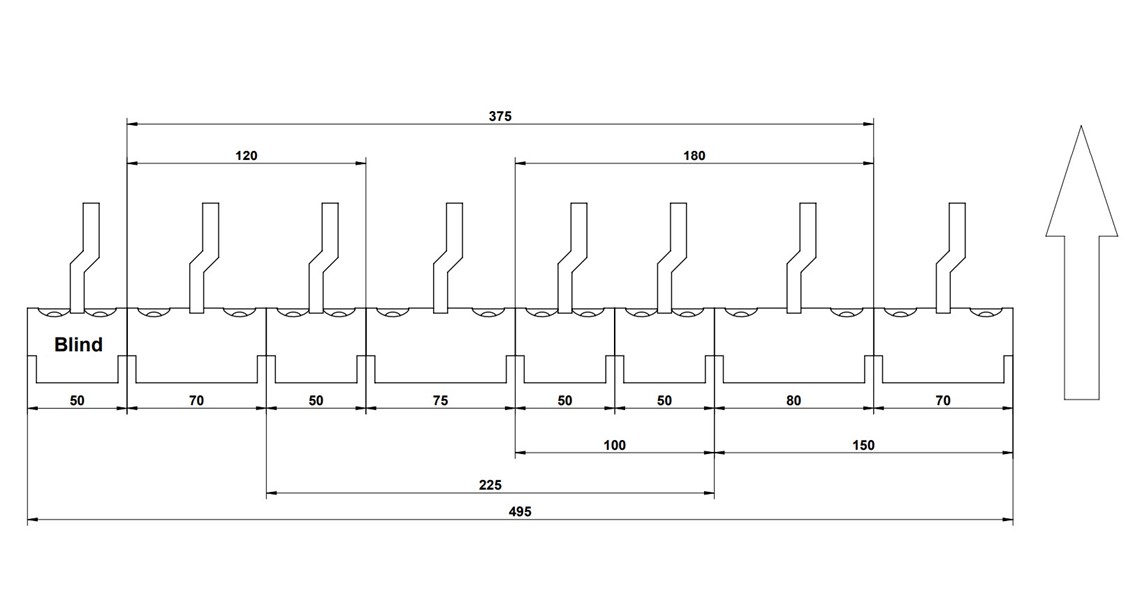

Line types that can be applied with the Thermoplastic Extruder

Below you can see the lines that are the most typically made with the Thermoplastic Extruder. However, using LineMaster computer and BM Online programme, you can program and create any type of lines you would prefer, using all the shutters of your extruder.

How does LineMaster computer support your line marking with the thermoplastic extruder?

Automatic control of marking equipment with the LineMaster computer

The LineMaster computer offers you full control over Thermoplastic Extruder. This makes it easy to control the application and make adjustments on the go without compromising on the quality of the markings.

It is possible to store up to 99 different line types and to arrange these in up to 30 different marking programs. You are also able to pre-set line widths, line types, colours and combinations to have them ready for marking, and can instantly adjust them on the go.

The thermoplastic extruder is automatically adaptable to changes in speed. Within a specific speed range, the material pump can be set to automatically increase or decrease the circulation rate according to the speed of the machine and thus compensate for the difference in thermoplastic consumption at different speeds.

The feeding pump for the thermoplastic is also controlled by the LineMaster and can be adjusted while performing marking work. Furthermore, each shutter can be individually controlled from the LineMaster. So you can digitally control the shutters, without any mechanical interference.

.

Miss the dots?

Borum thermoplastic extruder can offer flat lines and profiled markings, however, if you wish to make round dots on the road, you should take a look at our Dot'n line equipment.

The Dot’n line road marking equipment offers a 3-in-1 solution for extruded thermoplastic markings. This equipment can apply flat lines, various types of profiled markings, dots, and unique combinations of lines and dots using only one extruder head.

.